By:Peter Huber

Posted By: BHIS

Source:www.bhis.com.au

Continued from first part…

“FREEZTEQ” as discussed in last weeks column is a unique and highly effective damp coursing system which has been patented in the UK and overseas and it offers several major advantages over other chemical techniques.

The system is based on siliconate solutions which are inserted into holes drilled into the mortar line of the wall to be treated being in the form of a circular section pre-frozen pellets which are inserted into the pre-drilled holes.

The slow melting system ensures a continuous water repellent barrier throughout the treated area, because the system depends on natural seepage (diffusion), which research has shown to be the most effective method for fluid distribution in masonry, accurate dosages can be readily achieved and application costs are thus remarkably low.

The “FREEZTEQ” or known as the Passive system, is suitable for damp coursing all types of walls including stone and rubble and has shown itself particularly effective in treatment of older properties.

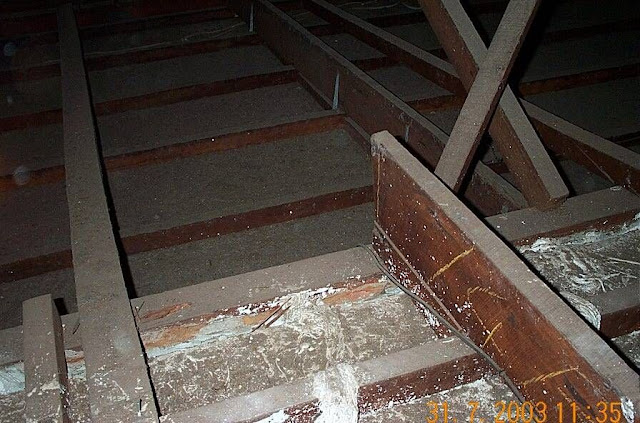

According to a spokesperson for “Consolidated Protective Coatings” who specialise in using the “FREEZTEQ” (444-2929) system say that, it is important to do a diagnostic analysis on the walls and then recommend which type of application to use in curing the rising damp. It apparently is not straight forward, since if the mechanical method is used, that is, injecting silicon liquid under pressure, then if the mortar is friable and the bricks are old and crumbly(Spalding) there is a good chance that they may fall apart or out, due to the Pressure that is used (between 50 to 120 psi) during the injection method. Hence the more Passive method comes into it’s own.

He also said that to perform a quality job the plaster needs to be removed and skirting which may be in the way all these will eventually have to be replaced and are reasonably costly items, but the choices are very limited.

Requirements for Damp-proof coursing and flashing materials are covered in detail in the AUSTRALIAN Standards 2904-1986

In fact if building a new home and the Builder is registered with the Builders Registration Board, a directive from the Board has been issued to the builders to make sure that all shower cubicles are water tight and that the home built in general does not leak as it will be the Builders responsibility for 6 years.

In summary the main causes for rising damp in older homes are, the break down of the original damp proofing needing chemical intervention) In newly built homes, poor quality and control of workmanship is usually the cause. There is no excuse with today’s technology, know how and information to have a damp or leaking abode.

Source: www.bhis.com.au/2012/10/how-to-cure-rising-damp-part-two/